Manufacturer of Water Heater 30 Liter - 30L-120L Electric/Geyser Water Heater – Yuxin

Manufacturer of Water Heater 30 Liter - 30L-120L Electric/Geyser Water Heater – Yuxin Detail:

Product introduction

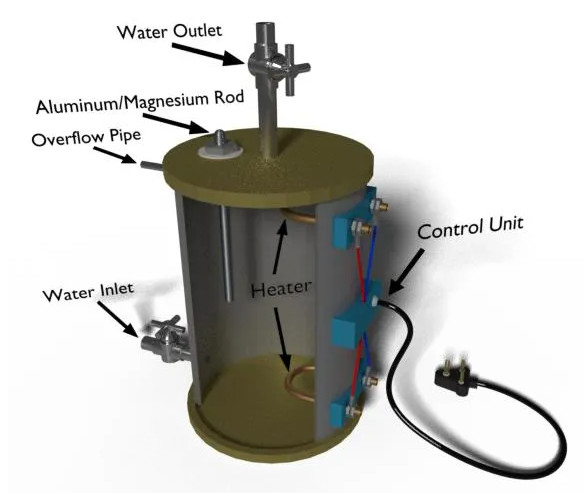

The basic principle water geyser is not very complex one. It is simple. Here electric heating element is used to heat up the water stored in a storage tank. The only difference from normal immersion type water heater, that it can automatically control the temperature the water by controlling the operating period of the heating elements associated with the geyser which cannot be possible in normal immersion type water heater.

Geyser heater is used for large quantity of water. Generally, from 20 ltr to 90 ltr capacity geysers are found in the market. In the storage tank, one or two heaters are fixed. For supplying of cold or hot water, specific pipe lines are fitted with the storage tank. That means there are inlet cold water and outlet hot water pipe. To control the flow of water, a valve is installed in the pipeline. To control the heat one thermostat switch is there. The switch gets automatically OFF to avoid misuse of heat. The entire body of the geyser is insulted. When the geyser storage tank is filled up, the water starts flowing through an overflow pipe, and then the inlet valve gets automatically OFF.

An anode rod made of aluminum or magnesium is screwed in the storage tank to reduce corrosion of metal body and metal parts of the water storage and supply system. This is because the metal of anode rod is more sensitive to corrosive reactions than the metal of the body structure of the system. Body of the storage tank is generally made of steel. As aluminum or magnesium is corroded faster, it makes the water soften before it can corrode the steel.

Certificates: CE,CCC, ISO9001, ISO14001, ISO45001,Safety

Specifications

| Specification | 80L | 100L | 120L |

| Model | YXJT80-L | YXJT100-L | YXJT120-L |

| Inner liner diameter (mm) | 370 | 370 | 370 |

| Water tank dimensions (mm) | Φ470*940mm Φ470*1140mm Φ470*1340mm | ||

| Inner liner plate and wall thickness (mm) | BTC210R or SPCC,1.8mm | ||

| Housing material and wall thickness (mm) | Colour coated board, 0.4mm, colour matt white | ||

| Inlet and outlet pipe and media orifice dimensions | G1/2 | ||

| Thickness of polyurethane insulation layer (mm) | Inner liner section 50mm, jacket section 39mm | ||

| Auxiliary heating power (KW) | 1.5KW | ||

| Heat transfer structure | Jacketed heat exchange, lower outlet | ||

| Heat exchanger material | SPCC, T=1.5mm | ||

| Rated working pressure | 0.7MPa | ||

Features

1.As a manufacturer of solar energy,we can offer customize for your local need and design your local system,print your logo etc.

2.OEM & ODM

3.Warranty 5 years

4.Online service (support video,picture),one-stop service from design to installation.

5.Quality guaranteed,product quality tests are carried out before leaving the factory.

6.Standard export package (wooden box or carton box with pallet)

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of sincerely, good religion and high quality are the base of enterprise development, we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for Manufacturer of Water Heater 30 Liter - 30L-120L Electric/Geyser Water Heater – Yuxin , The product will supply to all over the world, such as: Brasilia, Mecca, Ghana, Taking the core concept of to be the Responsible. We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!